clock

Monday 29 July 2013

Friday 12 July 2013

Basics of electronics and fundamentals of physics

here is the link where you find the max information about electronic subject.

https://www.khanacademy.org/science/physics/electricity-and-magnetism

https://www.khanacademy.org/science/physics/electricity-and-magnetism

Thursday 27 June 2013

K-MAPS SOFTWARE AND INTRODUCTION(karnaughs maps)

Karnaugh Map (K-Map)

A Karnaugh Map is a method of mapping truth tables onto a matrix that identifies places where two or more different combination of the input variables yield the same result. In addition to identifying redundant terms, the K map also cancels them, leaving only the minimized Boolean algebra expressions that will yield the same truth table outputs as the unreduced terms. The best way to understand K maps is to go through an actual simplification process using a K map.

We will start with a three variable truth table. Three variables have 2 to the 3'd, or 8 possible combination of 1’s and0's. This means that the K map must have 8 cells, one for even possible combination of input variables. The input variables can be mapped in any order on the K map, but it must follow the same organization as the truth table being mapped. We will assign the letters R, S, & T to the input variables of our truth table, and X to the output.

The Karnaugh map is laid out so that from cell to cell and from edge to edge, there is only a one bit change in the variables at any given time. This accounts for the column to column and row to row order of 00 01 11 10 (Gray Code). The column variables are assigned across the top of

the map, and the row variables are assigned to the left side of the map. Each cell contains the result of the variables for the binary combination given by the intersecting row and column. If the column variables are R S and the row variables are T U for a 16 cell or four variable map, the combination 0 1 1 0 is the same as (not R S T not U) or cell 6. If the truth table shows a 1 for the output at the position 0 1 1 0, then the Karnaugh map will contain a 1 in that particular cell.

As an example, Let's simplify the 3 bit K map above. Notice the four three variable expressions reduce down to three two variable expressions. This is a substantial savings in circuitry, and the equation will do exactly the same thing as the original unsimplified expression from the truth table.

The same method applies to larger K maps of 4, 5, and 6 variables. Four variable K maps have sixteen cells, since 2 to the 4 is 16. Five variable K maps are mapped as two, sixteen cell maps side by side. It is like mapping one map above the other, with the same numbered cells being redundant. Six variable K maps result in four, sixteen cell maps together in a square pattern. Top to bottom and side by side, redundancies are cancelled in the same numbered cells. More than four variable K maps are rarely used because they are more difficult to follow without getting lost.

A Karnaugh Map is a method of mapping truth tables onto a matrix that identifies places where two or more different combination of the input variables yield the same result. In addition to identifying redundant terms, the K map also cancels them, leaving only the minimized Boolean algebra expressions that will yield the same truth table outputs as the unreduced terms. The best way to understand K maps is to go through an actual simplification process using a K map.

We will start with a three variable truth table. Three variables have 2 to the 3'd, or 8 possible combination of 1’s and0's. This means that the K map must have 8 cells, one for even possible combination of input variables. The input variables can be mapped in any order on the K map, but it must follow the same organization as the truth table being mapped. We will assign the letters R, S, & T to the input variables of our truth table, and X to the output.

The Karnaugh map is laid out so that from cell to cell and from edge to edge, there is only a one bit change in the variables at any given time. This accounts for the column to column and row to row order of 00 01 11 10 (Gray Code). The column variables are assigned across the top of

the map, and the row variables are assigned to the left side of the map. Each cell contains the result of the variables for the binary combination given by the intersecting row and column. If the column variables are R S and the row variables are T U for a 16 cell or four variable map, the combination 0 1 1 0 is the same as (not R S T not U) or cell 6. If the truth table shows a 1 for the output at the position 0 1 1 0, then the Karnaugh map will contain a 1 in that particular cell.

As an example, Let's simplify the 3 bit K map above. Notice the four three variable expressions reduce down to three two variable expressions. This is a substantial savings in circuitry, and the equation will do exactly the same thing as the original unsimplified expression from the truth table.

The same method applies to larger K maps of 4, 5, and 6 variables. Four variable K maps have sixteen cells, since 2 to the 4 is 16. Five variable K maps are mapped as two, sixteen cell maps side by side. It is like mapping one map above the other, with the same numbered cells being redundant. Six variable K maps result in four, sixteen cell maps together in a square pattern. Top to bottom and side by side, redundancies are cancelled in the same numbered cells. More than four variable K maps are rarely used because they are more difficult to follow without getting lost.

Software to evaluate K-Map

This is a software to minimize a k-map using graphical interface and it can solve k-maps from 3-8 variables.

Click for better Quality...

This is a software to minimize a k-map using graphical interface and it can solve k-maps from 3-8 variables.

Click for better Quality...

CLICK HERE TO DOWNLOAD http://downloads.ziddu.com/downloadfile/5920489/minimalization.exe.html

Monday 24 June 2013

LEAD ACID BATTERY INFORMATION

How are they made and how do they

work ?

The lead acid battery is made up of a series of identical cells

each containing sets of positive and negative plates.

In semi traction cells flat plate construction is used. Each

positive plate is a cast metallic frame which contains the lead dioxide active

material. The negative plates contain spongy lead active material. also on a

similar frame. Both plates usually have the same surface areas.

In practice a typical cell is constructed with many more plates

than just two in order to get the required current output. All positive plates

are connected together as are all the negatives. Because each positive plate is

always positioned between two negative plates, there is always one or more

negative plate than positives.

The resultant voltage of lead acid cell is normally 2 volts In

order to achieve the voltage required for the application each cell is then

connected in series by substantial metal straps to form a battery. In a typical

monoblock battery, such as that used in a car for starting, the voltage

required is 12 volts, achieved by connecting six cells together in series and

enclosing them in one plastic box. Leisure batteries where a sustained current

requirement is needed and a deep cycle, the ability to be discharged to 90%,

have a different make-up to that of a traction battery that is used in a car.

The cell containing the plates is filled with an electrolyte

made up of sulphuric acid and distilled water with a specific gravity of 1.270

at 60deg F (15.6deg C). Sulphuric acid is a very active compound of hydrogen

and sulphur and oxygen atoms. Sulphuric acid is a very reactive substance and

because of its instability it is able to distribute itself very evenly

throughout the electrolyte in the battery. Over time, this action ensures that

an even reaction can occur between all the plates. producing voltage and

current. The chemical reaction between constituent parts of the electrolyte and

the 1. spongy lead of the negative plates and 2. the lead dioxide at the positive

plates turns the surface of both plates into lead sulphate. As this process

occurs the hydrogen within the acid reacts with the oxygen within the lead

dioxide to form water. The net result of all this reaction is that the positive

plate gives up electrons and the negative plate gains them in equal numbers,

thereby creating a potential difference between the two plates. The duration of

the reactions producing the cell voltage is limited if there is no connection

between the two plates and the voltage will remain constant.

If a connection (a load) is placed between the positive and

negative plates the chemical reaction is able to continue with electrons

flowing through the circuit from the negative plate to the positive. The flow

of electrons is in fact the current produced by the cell. Only when the supply

of electrons becomes depleted i.e. when the active material on the negative

plate has been used up, and the within the electrolyte has mostly been turned

into water will the battery fail to produce any current. During the chemical

process different levels of heating can occur and the faster a battery is

exhausted the greater will be the heating and thus the efficiency of the system

will be reduced.

Care and Maintenance of Flooded Lead

Acid Batteries

The most important aspects of care

for these and all other types of batteries concern both charge and discharge as

well as the mechanical treatment of the batteries i.e. keeping them topped up

with water etc.

It is important to consider that

lead acid (pb) batteries are, as we have seen above, quite delicate chemical

factories.

Discharge

Lead acid batteries should never be

run flat. The maximum recommended discharge is 75% of the total. This means

that the battery should have a minimum of 25% of charge remaining when it is

put on charge.

Lead acid batteries once filled with

electrolyte, should always be regularly charged even if they are not in use.

When left idle a filled battery will self discharge because of its own internal

resistance. left long enough a battery can go completely flat without ever

having been put into service. Storage also affects the rate of discharge. A

battery should never be stored directly on the ground and especially not on

concrete. The best storage method is wooden pallets which do not conduct or

allow damp paths and do allow good air circulation. During storage, most

manufacturers recommend a freshening charge once every two months or so.

How to find the state of charge

It is extremely difficult to

accurately measure the state of charge of a lead acid battery and to predict

the remaining capacity.

To determine the SOC (State Of

Charge) of a lead acid battery, the classic voltmeter approach does not work

well. The terminal voltage will vary widely between batteries as a function of

things like ambient temperature and the

relative age of the battery. A full set of temperature profile tables would show big differences in the open circuit terminal voltage over a wide temperature range. This is why a good charger must incorporate a temperature

compensation network to avoid ‘over’ or ‘under’ charging the battery at different ambient temperatures. To test a lead acid battery’s SOC, the best indicator is a hydrometer. When you test a battery’s SOC with a hydrometer, you are actually measuring the amount of sulfuric acid left in the electrolyte solution. As more energy is drained from the battery, the ratio of sulfuric acid to water decreases and the created lead sulfate byproduct begins forming on the

electrode plates. A low hydrometer reading means the chemical makeup that generates the free electrons is diminished so not as much energy is stored for use.

The term ‘specific gravity’ is often used to benchmark a lead acid battery’s SOC. The specific gravity of a substance is a comparison of its density to that of water (1.000). Imagine a one gallon bottle filled with water and a second

filled with feathers. There are equal volumes of material present in both but the bottle with the feathers will weigh less than that containing the water. The resultant specific gravity value of the bottle of feathers would be less than that of the bottle of water. With lead acid batteries, the sulfur atoms break down and leach out of the electrolyte solution as it discharges. The breakdown of the electrolyte reduces its overall ‘weight’ as the sulfur is removed from the solution thus reducing the specific gravity measurement. Take a look at the table below:

relative age of the battery. A full set of temperature profile tables would show big differences in the open circuit terminal voltage over a wide temperature range. This is why a good charger must incorporate a temperature

compensation network to avoid ‘over’ or ‘under’ charging the battery at different ambient temperatures. To test a lead acid battery’s SOC, the best indicator is a hydrometer. When you test a battery’s SOC with a hydrometer, you are actually measuring the amount of sulfuric acid left in the electrolyte solution. As more energy is drained from the battery, the ratio of sulfuric acid to water decreases and the created lead sulfate byproduct begins forming on the

electrode plates. A low hydrometer reading means the chemical makeup that generates the free electrons is diminished so not as much energy is stored for use.

The term ‘specific gravity’ is often used to benchmark a lead acid battery’s SOC. The specific gravity of a substance is a comparison of its density to that of water (1.000). Imagine a one gallon bottle filled with water and a second

filled with feathers. There are equal volumes of material present in both but the bottle with the feathers will weigh less than that containing the water. The resultant specific gravity value of the bottle of feathers would be less than that of the bottle of water. With lead acid batteries, the sulfur atoms break down and leach out of the electrolyte solution as it discharges. The breakdown of the electrolyte reduces its overall ‘weight’ as the sulfur is removed from the solution thus reducing the specific gravity measurement. Take a look at the table below:

|

State

of Charge as related to Specific

Gravity and Open-Circuit Voltage |

||

|

State

Of Charge

|

Specific

Gravity (sg)

|

Open-Circuit

Voltage (approximate) |

|

100%

|

1.265

|

12.63

|

|

75%

|

1.210

|

12.30

|

|

50%

|

1.160

|

12.00

|

|

25%

|

1.120

|

11.76

|

|

0%

|

1.100

|

11.64

|

Great care should be taken to avoid

discharging a battery beyond the 75% SOC point. Once the specific gravity drops

below the 1.210 level, excessive sulfate deposits form on the electrode plates.

This process is called ‘sulfation’ and leads to the hardening of the electrode

plates. If the battery is kept in a low charge state for long a period of time,

the sulfation process will eventually reduce the ability of the battery to

generate ion charge carries to the point that it no longer provides the needed

power. This point is otherwise known as a DEAD BATTERY!

When you recharge the battery, the process is reversed and the sulfur returns to the electrolyte solution. Proper cycling of the battery will ensure a long and functional life. If the battery is abused by allowing sulfation of the electrode plates on a regular basis or over an extended period of time, the charging process will not be able to restore the battery to its former full potential. Time to make a costly battery replacement!

When you recharge the battery, the process is reversed and the sulfur returns to the electrolyte solution. Proper cycling of the battery will ensure a long and functional life. If the battery is abused by allowing sulfation of the electrode plates on a regular basis or over an extended period of time, the charging process will not be able to restore the battery to its former full potential. Time to make a costly battery replacement!

Sulfation is mainly due to

undercharging. Here the sulfate ions have entered into deep bonds with the lead

on the cell's plates. The sulfate ions can bond with the lead at three

successively deeper energy levels. Level One is the bond we use when we

normally charge and discharge the cell. After a month or so at Level One, some

of the bonds form Level Two bonds which require more electric power to break.

After several months of being at Level Two bond, the sulfate ions really cozy

up to the lead and form Level Three bonds. Level Three bonds are not accessible

electrically. No amount of recharging will break Level Three bonds. The longer

the lead sulfate bond stays at a level the more likely it is to form a closer

acquaintance and enter the next deeper level. This is why it is so important to

fully, regularly, and completely, recharge lead-acid cells.

Equalization Charges

If the loss in capacity is due to Level Two bonding, then a repeated series of equalizing charges will break the Level Two bonds. Under equalization the Level Two bonds will first be transformed into Level One bonds, and then the sulfate ion can be kicked loose of the lead entirely and reenter the electrolyte solution. If your lead-acid cells have lost capacity, then a regime of equalizing charges is the first procedure to try. An equalization charge is a controlled overcharge of an already fully recharged cell. First recharge the cell and then continue to charge the cell at a C/20 rate for five to seven hours. During equalization charges, the cell voltage will become very high, about 2.7 VDC per cell. This overcharge contains the necessary power to break the Level Two bonds and force them to Level One. Once they reach Level One, the bond is easily broken and the sulfate ions reenter into solution in the electrolyte.

If the loss in capacity is due to Level Two bonding, then a repeated series of equalizing charges will break the Level Two bonds. Under equalization the Level Two bonds will first be transformed into Level One bonds, and then the sulfate ion can be kicked loose of the lead entirely and reenter the electrolyte solution. If your lead-acid cells have lost capacity, then a regime of equalizing charges is the first procedure to try. An equalization charge is a controlled overcharge of an already fully recharged cell. First recharge the cell and then continue to charge the cell at a C/20 rate for five to seven hours. During equalization charges, the cell voltage will become very high, about 2.7 VDC per cell. This overcharge contains the necessary power to break the Level Two bonds and force them to Level One. Once they reach Level One, the bond is easily broken and the sulfate ions reenter into solution in the electrolyte.

Battery capacity is not comparable

to a tank full of petrol. A filled petrol tank contains a finite amount of

energy which can be used either slowly or fast according to the energy

required. Battery capacity is not so simple.

In a battery, the rate of which

energy is drawn affects the overall amount of energy available from the

battery. For example , a 100 Ah battery rated at 20 hour rate means that over

20 hours there are 100 Ah available, or to put it another way you can expect to

draw up to 5 Amps per hour for up to 20 hours, 20x5=100Ah.

If you try to draw the battery down

more quickly you cannot expect to get the same amount of Ah from it. For

example if you draw it down over just one hour the approximate capacity will

become 100 x 0.59 which =59Ah. Putting this another way means that you can

connect a load on the battery which will draw 59 Amps for just one hour. If you

discharge over just half an hour you can only expect to get around half (47%)

the capacity from your batteries.

With most uses the rate at which a

battery is discharged varies enormously , you can see that any battery

condition indicator has to be quite a clever piece of equipment if it is ever

going to get close to giving an accurate reading.

Charging Lead Acid Batteries

Battery vent caps should always be

kept in place and tight during both charging and discharging.

For best battery life, i.e. greatest

number of charge/discharge cycles and years service most battery manufacturers

recommend that you should aim to recharge the batteries when they have reached

around 50% discharge. This level of discharge, of course, must be measured

according to the rate at which the battery is discharged, which as we have

already seen, varies the available total capacity of the battery.

In addition, some battery

manufacturers specify that best life will be achieved only if the batteries are

discharged sufficiently for a 4 hour bulk charge to take place before the

batteries are fully recharged.

A reasonable rule of thumb is that

you should aim to charge the batteries only when they are between 70% and 40%

discharged. If you charge them then they are only lightly discharged i.e. less

than 40% you will end up boiling them unnecessarily which wastes energy in the

form of heat and gassed off hydrogen and in turn shortens the life of the batteries.

In effect the batteries are being overcharged which can cause degradation and

buckling of the plates. In the process some active material is forced off the

plates and drops down to the bottom of the battery. If this occurs frequently

the eventual result is a build up of a bridge between the plates which in turn

can cause a possible short across the plates. This situation leads to the

destruction of a cell which then reduces the capacity of the battery.

To confuse matters further, a

battery will operate at its most efficient the deeper it is discharged, up to

around 75%. The bulk phase of the charge cycle is the most efficient and is

proportionately longer the deeper the discharge.

There are many battery chargers

available. Today, manufacturers supply automatic chargers which are supposed to

ensure optimum battery life. there are numerous charge profiles available and

now, with the advent of the electronic switch mode chargers, it is possible to

have a fully programmable charger on board your car capable of charging almost

any type of battery.

Lead acid batteries must be charged

carefully. If the charge is too violent and uncontrolled the batteries can

overheat and cause thermal run-away which can result in a possible explosion.

Too gently charging will take too

long to get the batteries fully charged with the result that the batteries will

end up being used in an under charged state eventually leading to premature

failure due to sulphation.

The latest electronic chargers

mostly make us the IUI charge profile for standard flooded lead acid batteries.

This means that the current drawn by the batteries is allowed to flow at a

constant (I) rate while the voltage is allowed to rise of its own accord, which

it will do as the battery starts to be charged up. This first part of the

charging cycle is known as the bulk charge phase. When a preset voltage has

been reached, normally the voltage at which the batteries just start to gas,

the charger will switch into the constant voltage (U) phase and the current

drawn by the battery will gradually drop until it hits another preset level.

This second part of the cycle is really the finish charge where the battery

just topped up to the brim very carefully at a much gently diminishing rate.

Finally the charger will switch again into the constant current mode (I) and

the voltage is allowed to rise again, up to a new higher preset limit, in order

to achieve a successful equalization charge.

The Bulk Charge

In this first part of the charge the

battery is allowed to have a large draw on the available current. Usually the

limit to this current level is determined by the availability of a suitably

sized mains outlet, especially on large batteries. It is however, worth noting

that that the life of a battery will be greatest if even this first bulk phase

of charging is started off gently and the maximum current is limited. If the

current is too high the result will be excess heating within the battery which

is wasteful and could lead to buckling of the plates and destruction of the

battery. Sizing of the charger to suit the batteries is important.

Finish charge

Once the bulk phase has been

completed, the finish phase commences and the battery charge is topped off.

This phase is very important. If the battery is not topped up gently it will

overflow in the form of waste heat and violent gassing of the plates which

again can lead to the plates buckling and the battery being destroyed. If the

battery is not topped up fully, it will become sulphated after only a few charges

and the result will be premature failure.

Equalization

In any cyclic application, a series

of batteries will always need to be equalized from time to time in order to

ensure that the battery cells remain at the same voltage throughout the pack.

No two battery cells or batteries

are created equal. During both charge and discharge each and every cell/battery

will react in a minutely different way to its neighbour. This could mean that

each battery may be holding a different quantity of charge. In order to get the

most out of the total battery pack it is necessary to make sure, as far as

possible, that each and every battery is holding a similar amount of charge.

During the charge cycle the voltages

of the different batteries will very. In order to bring them all to the same

level it is necessary to give some a slight overcharge in order to bring the

other up to full charge.

Equalization is done by allowing the

voltage to rise while allowing a small constant current to the batteries. The

voltage is allowed to rise above the normal finish voltage in order to allow

the weaker batteries/cells to draw more current. The stronger batteries will

not be adversely affected providing the current is gently and the period and

frequency of overcharging are not too high and great respectively. The stronger

batteries will absorb the overcharge by giving off heat by gently boiling and

gassing more heavily. Once the weaker batteries have absorbed the required

current, the equalization charge can be halted. The equalization time should be

long enough to bring all the batteries up to a full state of charge. As the

time factor will very the most reliable way to check the charge states is by a

voltmeter on each cell or individual battery.

Really sophisticated battery

charging and monitoring systems do not require the use of an equalization

charge and are able to charge all the batteries fully including the weaker ones

without overcharging the strong ones.

In these systems, each battery is

fitted with an electronic clamp, which gradually reduces the amount of charge

going into the fully charged batteries as the finish charge progresses. This

means that the weaker batteries receive more current to bring them up to a full

state of charge and the strong batteries are prevented from being overcharged

unnecessarily. The drawback with these sophisticated systems is their cost. The

price of each battery clamp can be in the order of 1/5 the cost of each

battery.

Watering

Traction and semi traction batteries are generally supplied

with removable vent caps so that they can be kept topped up with water. The

action of charging the batteries causes gassing when a certain voltage is

reached, usually somewhere around 2.35 to 2.4 volts per cell. The result is

that water is depleted of its constituent parts by liberation of the Hydrogen

gas plates. Hydrogen is of course much less dense that air and the electrolyte

and consequently floats out of the batteries at the earliest opportunity. This

water must therefore be replenished from time to time. If you do not gas a

battery the chances are that it will become sulphated due to fact that not all

the sulphate will be fully removed during the non gassing phase of charging.

It is very important to note that only very pure water is

suitable for topping up. It must contain no mineral traces and especially no

metallic solids, especially iron. The most suitable form of water is distilled

water or water that has been chemically treated and demineralised. Only these

types of water should ever be used to top up the batteries. Tap water will

quickly corrode the battery and should never be used. The frequency of topping

up required for the batteries depends on how they are used. If the are

frequently and heavily discharged they will need to be topped up regularly.

Perhaps every two weeks to a month.

If the batteries are not charged and discharged frequently then

it is likely that they will not require topping up for longer periods of time,

say once every two or three months or so.

If the batteries are regularly charged after only short

discharges they will use much more water than normally. This type of treatment

of the batteries should be avoided. It is most important to make sure that the

tops of the plates in a battery never become exposed. They should always be

covered by electrolyte or they will quickly sulphate and the battery will fail.

If watering is too much of a chore, It is possible to fit either automatic

watering systems or catalytic caps. With the former, the battery vent caps are

replaced with special caps, which incorporate float valves.

A series of hoses connect the float caps to a single filling

point. The filling point can be arranged so that distilled water is

poured into it from time to time or a reservoir can be fitted to constantly top

up the batteries. The catalyst caps prevent the battery charging gases from

venting to atmosphere and by chemical action combine the gases back into water.

Thus there is little or no water loss. Both the above systems work but there

are drawbacks. Lots of hoses interconnecting battery cells and batteries can

pose a serious safety threat if one of the cells goes into thermal run-away and

the vent caps block and the tubes have no water in them. The result is that

ignition from one cell will almost instantaneously result in ignition in all

the rest of the cells as the tubes will fill very quickly with hydrogen gas

which is extremely combustible and explosive, i.e. like the H bomb! A study by

Lucas back in the 1970s showed what can happen. In a demonstration, two

batteries were connected via their vent float caps by a 3-mm bore tube of a

length of over 60-ft. Combustion was artificially initiated in one battery and

within an almost immeasurably short time combustion occurred in the second

battery. The moral of this tale is that only vent float caps in first class

condition should be used and at around £5-00 to £8-00 each they are not cheap!

In addition, should the tubes ever become blocked or the floats fail to operate

correctly, it is highly likely that the batteries will not receive the correct

supply of water and the result will be failure of at least one cell.

The catalyst caps are possibly a better bet. They are however,

even more expensive and do not last for ever. Most sealed batteries make use of

a built in catalyst system.

The cheapest method of watering is by hand. It is also the most

reliable provided it is done regularly.

Temperature

Temperature affects charging as well as discharge. As a rough

rule of thumb, the cooler the temperature the more charge a battery will absorb

and the warmer the temperature the more it will discharge. There are of course

limits. However it is senseless to charge a battery that has just been

discharged fast and has been left out in the sun. In these circumstances it

must be allowed to cool before charging is initiated. The ideal charging

temperature varies but a reasonable guide is between 15 and 25 degrees

Centigrade. Ideal discharge temperatures are between 20 and 30 degrees

centigrade. Unfortunately discharging a battery at a higher temperature, while

desirably affecting its performance, will adversely affect its life. In fact,

so far as I can determine almost every battery manufacturer can work out the

number of Ah which can be drawn from any battery over its life under given

constant discharge conditions. There does appear to be a finite number of Ah

that can be drawn from a battery for a given discharge profile. Predicting this

discharge profile is the difficult bit!

Teardown of the mysterious KMS 4-port USB charger

Teardown of the mysterious KMS 4-port USB charger

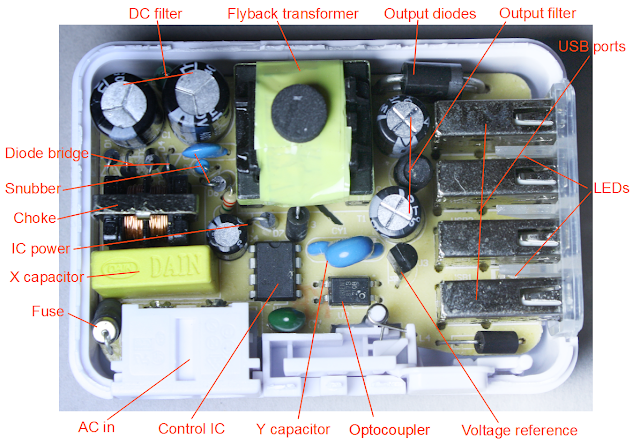

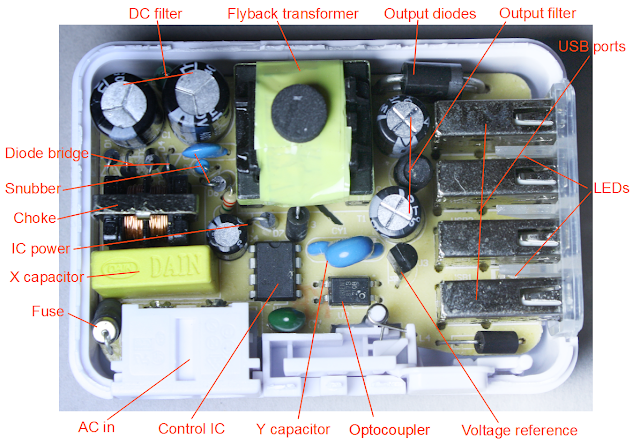

In this article I tear down a 4-port USB charger of puzzling origin.

This charger is a huge step above the $2 counterfeit chargers I examined earlier

in design and manufacture, but considerably below the quality of

name-brand chargers. Likewise with safety - the charger was built with

some attention to safety, but appears to fall short of UL standards.

One puzzle about this charger is it's unclear who makes it and what model it is. The case says it's the KMS AC-09 but the circuit board says "TC09-new-V4.2". Amazon lists the brand as "Cosmos®", but I couldn't find any sign that KMS or Cosmos are actual companies. After some web searches, I think the charger is built by Guangzhou Panyu Qiaonan Saidi Electronic Factory (more) as the TC09 charger for $5.30 wholesale, or maybe HK Yingjia International, a consumer electronics manufacturer in Shenzhen (more). In any case, I'll call this the "KMS charger" since I need to call it something.

In my previous lab analysis of 12 chargers, I compared a dozen different chargers in 9 different categories, rating them from 1 to 5 'bolts' and the KMS charger came in about average in terms of performance. The results for the KMS charger are summarized below. For details on these measurements, see my previous article A dozen USB chargers in the lab).

The charger looks mostly safe, although it doesn't have UL certification and I suspect it would fail certification. The 6mm clearance between the primary and secondary looks solid. However, the transformer windings are only separated by 3mm, rather than 6mm, as I show below. (This is still much superior to the $2 chargers that have almost no separation.)

One interesting feature of the power supply is the power plug can be interchanged for use in different countries. (Some other chargers such as the HP TouchPad and Apple iPad are similar.)

The charger has some quality issues. The power quality measurements I did in my previous article show the KMS charger has fairly poor quality output, with a lot of noise in the output.

The IC datasheet recommends 200 mm2 of foil on the IC output pins to provide cooling. I measured about 18 mm2 (less than 10% of recommended), which suggests the charger may overheat under full load.

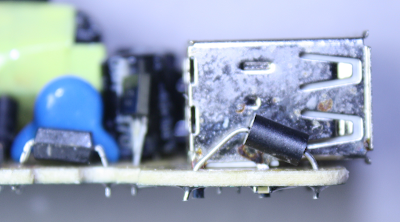

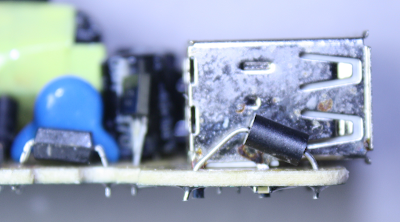

The above photo shows that the build quality of the charger is not extremely high. The inductor at the front right is very crooked, and the optocoupler at the left is somewhat crooked. While this doesn't affect the performance, it shows the assembly was rapid rather than careful. More concerning, some of the solder joints appear to be almost bridged, which could cause catastrophic failure of the charger. I also found a government report of a KMS charger catching fire, apparently due to a loose wire in the power plug.

One unique feature of the charger is the blue LEDs which cause it to emit an eerie blue glow when in use. A lot of users dislike this though (according to reviews), because the light is distracting at night.

For readers interested in circuits, I have prepared the above

approximate schematic (click for a larger view). The circuit is pretty

straightforward compared to other chargers (look at my iPhone charger schematic

for comparison). Starting at the upper left, the input AC is converted

to DC by the diode bridge, and then filtered by a simple

inductor-capacitor filter. This high-voltage DC is connected to the

flyback transformer primary. The THX203H control IC switches the other

side of the flyback transformer to ground through the current-sense

resistors R12A and R12B and inductor L3. (Most chargers use a separate

switching transistor, but in this charger, the transistor is inside the

control IC.) The snubber circuit R2, C3, and D6 absorbs some of the

high-frequency switching spikes (although looking at the output below,

this circuit isn't entirely successful). The auxiliary transformer

winding and D7 and C4 provide the DC power to the control IC. The

optocoupler provides feedback to the IC, indicating the output voltage

level.

For readers interested in circuits, I have prepared the above

approximate schematic (click for a larger view). The circuit is pretty

straightforward compared to other chargers (look at my iPhone charger schematic

for comparison). Starting at the upper left, the input AC is converted

to DC by the diode bridge, and then filtered by a simple

inductor-capacitor filter. This high-voltage DC is connected to the

flyback transformer primary. The THX203H control IC switches the other

side of the flyback transformer to ground through the current-sense

resistors R12A and R12B and inductor L3. (Most chargers use a separate

switching transistor, but in this charger, the transistor is inside the

control IC.) The snubber circuit R2, C3, and D6 absorbs some of the

high-frequency switching spikes (although looking at the output below,

this circuit isn't entirely successful). The auxiliary transformer

winding and D7 and C4 provide the DC power to the control IC. The

optocoupler provides feedback to the IC, indicating the output voltage

level.

On the secondary side, the high-speed Schottky diodes (D5) convert the transformer output to DC. This is then filtered through an inductor-capacitor filter that smooths it out. The output voltage feedback is generated by the TL431A regulator and fed into the optocoupler.[1]

Finally, the actual USB output circuitry has more components than you'd expect. For each pair of ports, four resistors set the D+ and D- voltages to indicate to devices that the charger is (pretending to be) an Apple 2A charger. Each port has a small bypass capacitor to smooth out power transients. Finally there are two blue LEDs with current-limiting resistors to provide the blue glow.

The controller IC poses a bit of a mystery. It's labeled as the THX 203H controller, which turns out to be manufactured by NanJing TongHuaXin Electronic Co, Ltd., a Chinese switching power supply chip company (details). The datasheet for this part is very hard to understand, as it is machine-translated from Chinese, for example:

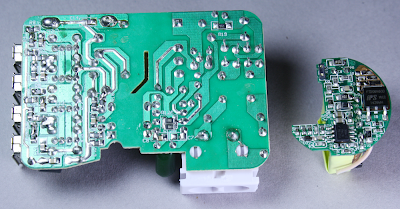

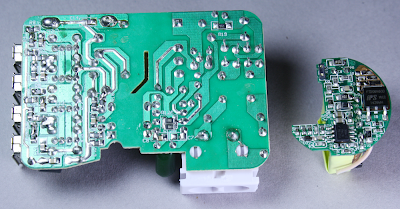

The above picture shows the KMS charger circuit board on the left and a

circuit board from the HP TouchPad charger on the right.

Compact phone chargers such as the iPhone or TouchPad chargers go to

amazing effort to pack the components as tightly as possible. The KMS

charger on the other hand has a much more spacious design with a lot of

wasted space. Since any charger with 4 USB ports is going to be fairly

large, they probably figured it's not worth the effort to make the rest

of the circuitry compact. The difference in density between the two

circuit boards is striking, though.

The above picture shows the KMS charger circuit board on the left and a

circuit board from the HP TouchPad charger on the right.

Compact phone chargers such as the iPhone or TouchPad chargers go to

amazing effort to pack the components as tightly as possible. The KMS

charger on the other hand has a much more spacious design with a lot of

wasted space. Since any charger with 4 USB ports is going to be fairly

large, they probably figured it's not worth the effort to make the rest

of the circuitry compact. The difference in density between the two

circuit boards is striking, though.

A key safety feature of the KMS charger is visible in the middle of the circuit board - note the angular cut-out slot, and the empty vertical region with no circuitry. This isolates the high-voltage circuits on the right from the low-voltage output circuits on the left. The KMS charger has a safe 6mm gap and the cut-out provides additional creepage distance. Counterfeit chargers usually skip this critical safety feature, with only a millimeter or two keeping the high voltage from reaching the output and shocking the user.

You might wonder how the charger works if the high voltage and low voltage circuits are separated by a gap. The key is that any components that cross this gap must be specially designed to avoid electrical hazards. The key component is the flyback transformer, which transfers the power through magnetic fields, avoiding any direct electrical connection between the two sides. The feedback signal passes from the secondary to the primary through an optocoupler, which transmits the feedback through a light signal, again avoiding an electrical connection. Finally, a Y safety capacitor connects the primary and secondary grounds to reduce electrical noise. The design of a Y capacitor ensures it won't pass dangerous electrical currents, and won't short out even under fault conditions.

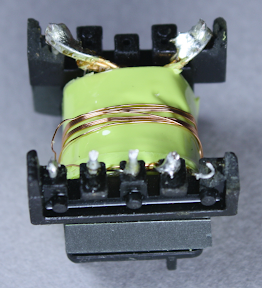

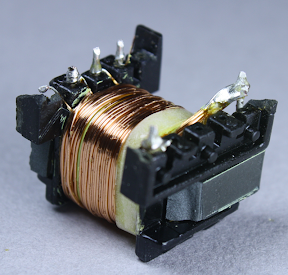

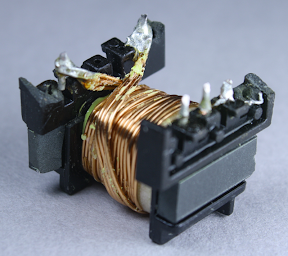

Under the first layers of insulating tape is a copper 'belly band' which surrounds the transformer to provide noise shielding from eddy currents in the transformer.[2] This copper shielding is omitted from super-cheap transformers, showing that this charger goes beyond the minimum.

The windings are all separated by insulating tape. Under the belly band and insulating tape is the auxiliary winding, which provides power to the control IC. You might wonder why the IC needs a separate power supply instead of using the USB power output, but this wouldn't be safe because the USB output would no longer be isolated from the input. This winding is 9 turns of wire; since the IC requires low current, the wire is fairly thin.

Above you can see half of the primary winding, which is fed by the input power. This winding has 40 turns of wire.

An interesting safety feature is the 3 mm "margin tape"[3] to the lower right of the winding, which ensures that the primary winding stays 3 mm away from the edge. I was interested to see this, since other transformers I've disassembled use triple-insulated wire instead of boundary tape. To ensure safe electrical isolation between the primary and secondary windings, either the secondary wires need to be triple-insulated, or there needs to be at least 6mm of distance between the windings. Super-small chargers don't have 3mm of extra room, so they use the more expensive triple-insulated wire. But since the KMS is larger, it uses the 3mm margin tape. I'm not an expert on safety requirements, but it looks like this transformer doesn't quite meet the requirements. Normally, the margin tape is put on both sides, so there's a total of 6mm creepage distance between the windings.[4][5] But since the tape is only on one side, the windings only have half of the required distance.

The secondary winding provides the low-voltage high-current output with 8 turns of wire. In order to support 2 amps, this winding has thick wire with four strands in parallel. I haven't seen parallel strands like this before, probably because the KMS charger supplies higher power. Note the 3mm margin tape keeping the winding away from the edge.

Finally, the second half of the primary winding forms the innermost layer of the transformer; this is also 40 turns of wire. The primary winding is split into two layers that surround the secondary winding for better electrical properties. Note that the primary winding is 80 turns, while the secondary output winding is 8 turns. To oversimplify a bit, this means the output will be 10 times the current of the input at 1/10 the voltage, which is how the high voltage low current input results in the low voltage high current output. The above picture gives a good view of the 3mm margin tape at the right that keeps the wire away from the edge of the core.

By looking at the output voltage and frequency spectrum, we can determine a fair bit about how the device operates. I measured a constant 60 kHz switching frequency above 1 amp output load, but a dropping frequency for lower loads. The datasheet gives some clues to this behavior. The power supply normally operates using PWM (pulse width modulation). The switching frequency is constant, but the amount of time the power transistor is on varies. The longer it is on, the more power into the transformer and the more output power. This matches the observed behavior from 1 amp to 3.5 amps. The datasheet also describes how the switching frequency drops under low power, which matches what I observed below 1 amp.

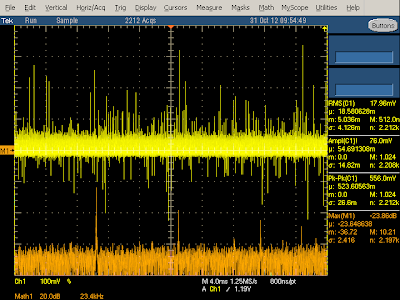

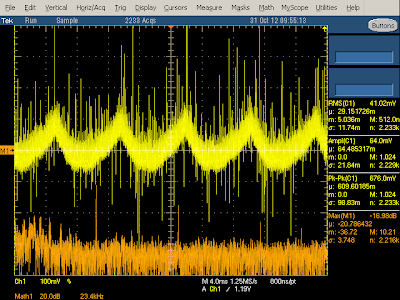

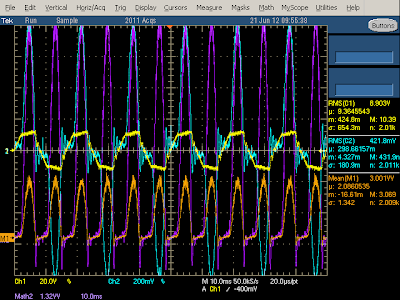

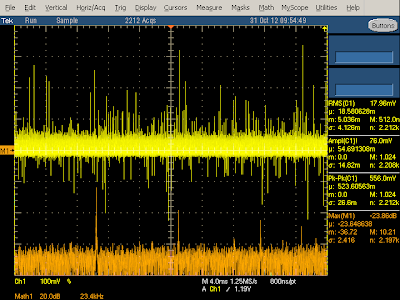

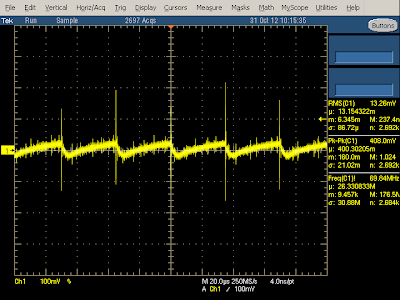

The above oscilloscope trace illustrates the behavior when producing 2 amps. The frequency spectrum shows narrow peaks (orange) at the 60 kHz switching frequency and harmonics. The yellow output voltage shows a bunch of large spikes due to the power switching on and off - this indicates that the charger isn't filtering the output very well, letting these spikes get into the connected device.

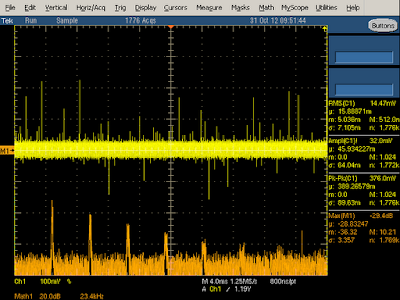

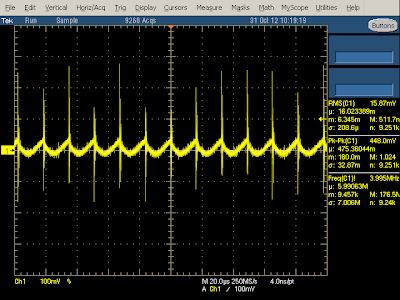

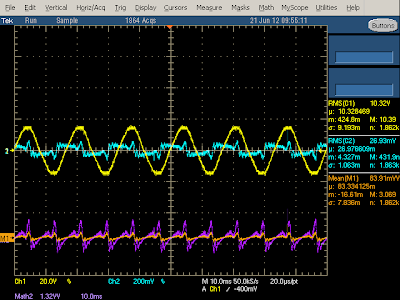

The diagram below zooms in to show the output in more detail. Each spike is when the switching transistor turns on at 60 kHz. The output power drops as the current through the flyback transformer increases (since the transformer secondary is blocked by the diode at this time). The output then climbs when the transistor switches off and the power is transferred to the secondary.

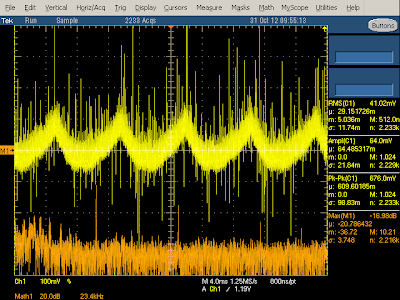

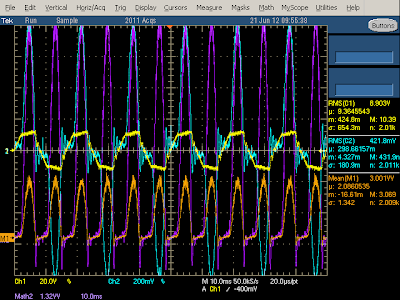

As the charger load increases above 3 amps, the quality of the output significantly decreases, and large 120 Hz ripple appears in the output (yellow). This is probably because the input capacitors can't store enough power to provide a constant output at this high load. Since the charger is only rated to provide 2.1 amps of output, I don't consider this a design flaw, but it's interesting to see this behavior in the output. The key result here is not to overload the charger, because the power quality gets much worse.

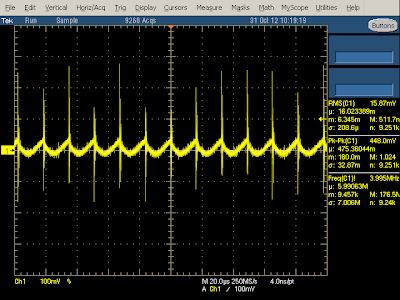

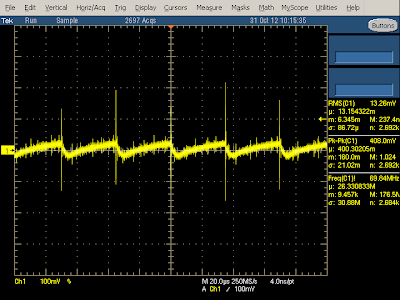

The charger is designed to reduce the switching frequency under low load for efficiency. I found this feature kicks in at loads under 1 amp, with the switching frequency smoothly dropping from 60 kHz to 29 kHz at 250 mA load and even lower under no load. The graph below shows the frequency spectrum at 250 mA load. Note that the spikes are wider than the previous case since the frequency becomes more unstable when it is reduced.

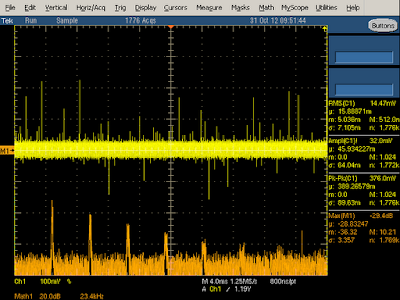

The output waveform below at 250 mA is similar to the previous (2A) case, except at a lower frequency. Note that the output still has large spikes when the transistor switches on. The output voltage drops while the switching transistor is on and then rises while the transistor is off (due to the flyback design), so you can see below that the transistor is off most of the time at low power.

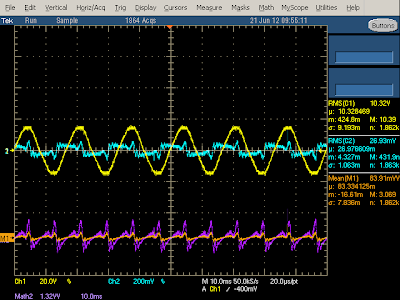

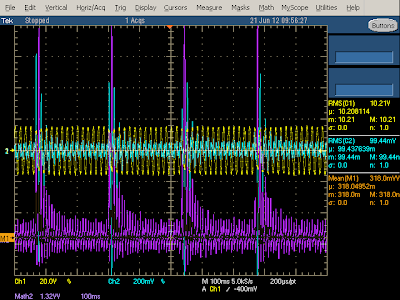

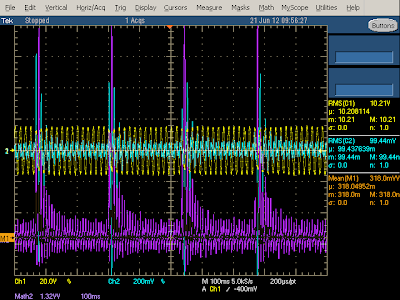

The oscilloscope output below shows the power usage of the charger under no load. The line input voltage (yellow) is a nice sine wave, but the current (cyan) is very irregular. There is a bump corresponding to the voltage peaks as the input diodes conduct and re-charge the filter capacitors. The remaining current oscillations are unusual - I haven't seen them in other chargers, and I expect they are due to the large input choke. From the orange line you can see that the power usage has small spikes at 120 Hz. Taking the power factor into account and computing real power shows the charger uses 180 mW when idle which is fairly high, but actually lower than the Apple iPhone charger.

With load applied to the charger, the power usage shoots up as shown below. I compute the power usage as 6.4 watts, while the charger is supplying 4.4 watts to the output, for an efficiency of 69%. The shape of the current curve (cyan) and power curve (orange) shows that the charger is taking line power about half the time (the big curved peaks), and not for the other half (the flat oscillations in between). This illustrates the bad power factor that switching power supplies have. (PC power supplies often use power factor correction (PFC) circuits to improve the power factor.)The yellow input voltage curve is somewhat distorted, probably due to the lame isolation transformer I used.

You might wonder what happens if you short-circuit the output of the charger. It is designed to shut down before damage occurs, rather than self-destruct. After the internal voltage drops, the charger will start up again, and repeat this cycle until the problem goes away. This is called "hiccup mode", since the charger generates hiccups of power. The oscilloscope trace below shows the power consumption of the KMS charger when shorted. Note the pulses as it start up and shuts down every 250 milliseconds.

Like most power supplies, the charger uses a TL431A for the voltage feedback.[1] This TL431A is produced by Wing Shing Computer Components The optocoupler is an ORPC 817B optocoupler from Shenzen Orient Technology Co., Ltd. (I don't want to speculate on the cultural significance of their raising the flag over Iwo Jima company logo.)

,

customer ratings for this charger are split between people who love it

and people who hate it, which seems reasonable given what I saw in the

teardown.

Thanks to Gary F. for providing the charger.

,

customer ratings for this charger are split between people who love it

and people who hate it, which seems reasonable given what I saw in the

teardown.

Thanks to Gary F. for providing the charger.

One puzzle about this charger is it's unclear who makes it and what model it is. The case says it's the KMS AC-09 but the circuit board says "TC09-new-V4.2". Amazon lists the brand as "Cosmos®", but I couldn't find any sign that KMS or Cosmos are actual companies. After some web searches, I think the charger is built by Guangzhou Panyu Qiaonan Saidi Electronic Factory (more) as the TC09 charger for $5.30 wholesale, or maybe HK Yingjia International, a consumer electronics manufacturer in Shenzhen (more). In any case, I'll call this the "KMS charger" since I need to call it something.

In my previous lab analysis of 12 chargers, I compared a dozen different chargers in 9 different categories, rating them from 1 to 5 'bolts' and the KMS charger came in about average in terms of performance. The results for the KMS charger are summarized below. For details on these measurements, see my previous article A dozen USB chargers in the lab).

| Overall rating |  |

|---|---|

| Vampire (idle) power usage |  |

| Efficiency under load |  |

| Achieves power rating |  |

| Spikes in output |  |

| High-frequency noise in output |  |

| Ripple in output |  |

| Voltage sag |  |

| Current sag |  |

| Regulation quality |  |

The good and the bad

Overall, this charger is much higher quality than the $2 counterfeit chargers, but considerably lower quality than name-brand chargers. The charger provides more filtering than basic chargers, from the large input choke to the multiple output inductors. It includes X and Y capacitors for filtering.The charger looks mostly safe, although it doesn't have UL certification and I suspect it would fail certification. The 6mm clearance between the primary and secondary looks solid. However, the transformer windings are only separated by 3mm, rather than 6mm, as I show below. (This is still much superior to the $2 chargers that have almost no separation.)

One interesting feature of the power supply is the power plug can be interchanged for use in different countries. (Some other chargers such as the HP TouchPad and Apple iPad are similar.)

The charger has some quality issues. The power quality measurements I did in my previous article show the KMS charger has fairly poor quality output, with a lot of noise in the output.

The IC datasheet recommends 200 mm2 of foil on the IC output pins to provide cooling. I measured about 18 mm2 (less than 10% of recommended), which suggests the charger may overheat under full load.

The above photo shows that the build quality of the charger is not extremely high. The inductor at the front right is very crooked, and the optocoupler at the left is somewhat crooked. While this doesn't affect the performance, it shows the assembly was rapid rather than careful. More concerning, some of the solder joints appear to be almost bridged, which could cause catastrophic failure of the charger. I also found a government report of a KMS charger catching fire, apparently due to a loose wire in the power plug.

One unique feature of the charger is the blue LEDs which cause it to emit an eerie blue glow when in use. A lot of users dislike this though (according to reviews), because the light is distracting at night.

The circuit

For readers interested in circuits, I have prepared the above

approximate schematic (click for a larger view). The circuit is pretty

straightforward compared to other chargers (look at my iPhone charger schematic

for comparison). Starting at the upper left, the input AC is converted

to DC by the diode bridge, and then filtered by a simple

inductor-capacitor filter. This high-voltage DC is connected to the

flyback transformer primary. The THX203H control IC switches the other

side of the flyback transformer to ground through the current-sense

resistors R12A and R12B and inductor L3. (Most chargers use a separate

switching transistor, but in this charger, the transistor is inside the

control IC.) The snubber circuit R2, C3, and D6 absorbs some of the

high-frequency switching spikes (although looking at the output below,

this circuit isn't entirely successful). The auxiliary transformer

winding and D7 and C4 provide the DC power to the control IC. The

optocoupler provides feedback to the IC, indicating the output voltage

level.

For readers interested in circuits, I have prepared the above

approximate schematic (click for a larger view). The circuit is pretty

straightforward compared to other chargers (look at my iPhone charger schematic

for comparison). Starting at the upper left, the input AC is converted

to DC by the diode bridge, and then filtered by a simple

inductor-capacitor filter. This high-voltage DC is connected to the

flyback transformer primary. The THX203H control IC switches the other

side of the flyback transformer to ground through the current-sense

resistors R12A and R12B and inductor L3. (Most chargers use a separate

switching transistor, but in this charger, the transistor is inside the

control IC.) The snubber circuit R2, C3, and D6 absorbs some of the

high-frequency switching spikes (although looking at the output below,

this circuit isn't entirely successful). The auxiliary transformer

winding and D7 and C4 provide the DC power to the control IC. The

optocoupler provides feedback to the IC, indicating the output voltage

level.

On the secondary side, the high-speed Schottky diodes (D5) convert the transformer output to DC. This is then filtered through an inductor-capacitor filter that smooths it out. The output voltage feedback is generated by the TL431A regulator and fed into the optocoupler.[1]

Finally, the actual USB output circuitry has more components than you'd expect. For each pair of ports, four resistors set the D+ and D- voltages to indicate to devices that the charger is (pretending to be) an Apple 2A charger. Each port has a small bypass capacitor to smooth out power transients. Finally there are two blue LEDs with current-limiting resistors to provide the blue glow.

The controller IC poses a bit of a mystery. It's labeled as the THX 203H controller, which turns out to be manufactured by NanJing TongHuaXin Electronic Co, Ltd., a Chinese switching power supply chip company (details). The datasheet for this part is very hard to understand, as it is machine-translated from Chinese, for example:

The startup circuit inside IC is designed as a particular current inhalation way, so it can start up with the magnification function of the power switch tube itself.After some more investigation, this chip seems to be the SDC603 Current Mode PWM Controller designed by SDC Semi (Shaoxing Devechip Microelectronics Co., Ltd.). This is a Chinese state-level R&D center that is part of China's Torch Plan Project to develop high-tech industries. (Also check out the SDC company song.) The controller chip is a basic 8-pin current-mode PWM controller chip. It includes a built-in NPN power transistor, which reduces the charger part count. The chip can produce 12 watts output power.

Circuit board

The above picture shows the KMS charger circuit board on the left and a

circuit board from the HP TouchPad charger on the right.

Compact phone chargers such as the iPhone or TouchPad chargers go to

amazing effort to pack the components as tightly as possible. The KMS

charger on the other hand has a much more spacious design with a lot of

wasted space. Since any charger with 4 USB ports is going to be fairly

large, they probably figured it's not worth the effort to make the rest

of the circuitry compact. The difference in density between the two

circuit boards is striking, though.

The above picture shows the KMS charger circuit board on the left and a

circuit board from the HP TouchPad charger on the right.

Compact phone chargers such as the iPhone or TouchPad chargers go to

amazing effort to pack the components as tightly as possible. The KMS

charger on the other hand has a much more spacious design with a lot of

wasted space. Since any charger with 4 USB ports is going to be fairly

large, they probably figured it's not worth the effort to make the rest

of the circuitry compact. The difference in density between the two

circuit boards is striking, though.

A key safety feature of the KMS charger is visible in the middle of the circuit board - note the angular cut-out slot, and the empty vertical region with no circuitry. This isolates the high-voltage circuits on the right from the low-voltage output circuits on the left. The KMS charger has a safe 6mm gap and the cut-out provides additional creepage distance. Counterfeit chargers usually skip this critical safety feature, with only a millimeter or two keeping the high voltage from reaching the output and shocking the user.

You might wonder how the charger works if the high voltage and low voltage circuits are separated by a gap. The key is that any components that cross this gap must be specially designed to avoid electrical hazards. The key component is the flyback transformer, which transfers the power through magnetic fields, avoiding any direct electrical connection between the two sides. The feedback signal passes from the secondary to the primary through an optocoupler, which transmits the feedback through a light signal, again avoiding an electrical connection. Finally, a Y safety capacitor connects the primary and secondary grounds to reduce electrical noise. The design of a Y capacitor ensures it won't pass dangerous electrical currents, and won't short out even under fault conditions.

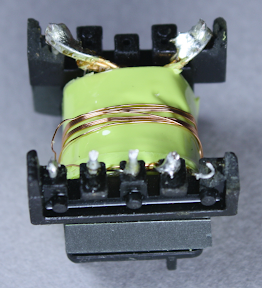

Transformer teardown

The flyback transformer is the key component of a charger and usually the largest and most expensive. The transformer is where the high input voltage is converted to the output voltage, and the two voltages are in extremely close proximity, so the safety of the transformer is critical. From the outside, you can't tell if the manufacturer saved a few cents by leaving out most of the insulation, as happens with $2 chargers. I tore apart the transformer of the KMS charger to see what's inside. The black circle on top of the transformer seen earlier is simply a foam disk, which helps reduce transformer noise by padding the transformer against the case. If a charger makes a high-pitched noise, it's usually coming from the transformer. Power supplies are usually designed with switching frequencies higher than people can hear, but in some circumstances it's still audible, especially if you are young and haven't lost high frequency hearing.

Under the first layers of insulating tape is a copper 'belly band' which surrounds the transformer to provide noise shielding from eddy currents in the transformer.[2] This copper shielding is omitted from super-cheap transformers, showing that this charger goes beyond the minimum.

The windings are all separated by insulating tape. Under the belly band and insulating tape is the auxiliary winding, which provides power to the control IC. You might wonder why the IC needs a separate power supply instead of using the USB power output, but this wouldn't be safe because the USB output would no longer be isolated from the input. This winding is 9 turns of wire; since the IC requires low current, the wire is fairly thin.

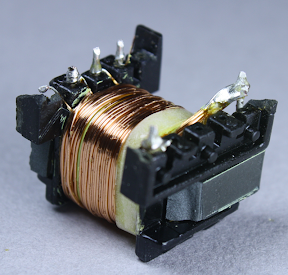

Above you can see half of the primary winding, which is fed by the input power. This winding has 40 turns of wire.

An interesting safety feature is the 3 mm "margin tape"[3] to the lower right of the winding, which ensures that the primary winding stays 3 mm away from the edge. I was interested to see this, since other transformers I've disassembled use triple-insulated wire instead of boundary tape. To ensure safe electrical isolation between the primary and secondary windings, either the secondary wires need to be triple-insulated, or there needs to be at least 6mm of distance between the windings. Super-small chargers don't have 3mm of extra room, so they use the more expensive triple-insulated wire. But since the KMS is larger, it uses the 3mm margin tape. I'm not an expert on safety requirements, but it looks like this transformer doesn't quite meet the requirements. Normally, the margin tape is put on both sides, so there's a total of 6mm creepage distance between the windings.[4][5] But since the tape is only on one side, the windings only have half of the required distance.

The secondary winding provides the low-voltage high-current output with 8 turns of wire. In order to support 2 amps, this winding has thick wire with four strands in parallel. I haven't seen parallel strands like this before, probably because the KMS charger supplies higher power. Note the 3mm margin tape keeping the winding away from the edge.

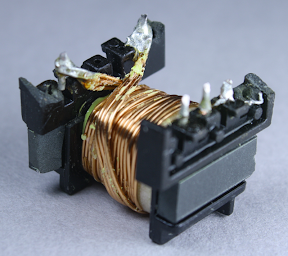

Finally, the second half of the primary winding forms the innermost layer of the transformer; this is also 40 turns of wire. The primary winding is split into two layers that surround the secondary winding for better electrical properties. Note that the primary winding is 80 turns, while the secondary output winding is 8 turns. To oversimplify a bit, this means the output will be 10 times the current of the input at 1/10 the voltage, which is how the high voltage low current input results in the low voltage high current output. The above picture gives a good view of the 3mm margin tape at the right that keeps the wire away from the edge of the core.

Measuring the charger in use

The charger is a switching power supply using a flyback transformer. How this works is the high voltage DC is switched on and off tens of thousands of times a second by the control IC. These pulses of DC are sent into the flyback transformer. A flyback transformer is different from normal transformers in that the output diode blocks power from flowing out of the transformer while power is flowing in. Instead, as the current increases, power is stored in the transformer as a magnetic field. When the input current switches off, the stored power then flows out of the transformer, providing the desired output.By looking at the output voltage and frequency spectrum, we can determine a fair bit about how the device operates. I measured a constant 60 kHz switching frequency above 1 amp output load, but a dropping frequency for lower loads. The datasheet gives some clues to this behavior. The power supply normally operates using PWM (pulse width modulation). The switching frequency is constant, but the amount of time the power transistor is on varies. The longer it is on, the more power into the transformer and the more output power. This matches the observed behavior from 1 amp to 3.5 amps. The datasheet also describes how the switching frequency drops under low power, which matches what I observed below 1 amp.

The above oscilloscope trace illustrates the behavior when producing 2 amps. The frequency spectrum shows narrow peaks (orange) at the 60 kHz switching frequency and harmonics. The yellow output voltage shows a bunch of large spikes due to the power switching on and off - this indicates that the charger isn't filtering the output very well, letting these spikes get into the connected device.

The diagram below zooms in to show the output in more detail. Each spike is when the switching transistor turns on at 60 kHz. The output power drops as the current through the flyback transformer increases (since the transformer secondary is blocked by the diode at this time). The output then climbs when the transistor switches off and the power is transferred to the secondary.

As the charger load increases above 3 amps, the quality of the output significantly decreases, and large 120 Hz ripple appears in the output (yellow). This is probably because the input capacitors can't store enough power to provide a constant output at this high load. Since the charger is only rated to provide 2.1 amps of output, I don't consider this a design flaw, but it's interesting to see this behavior in the output. The key result here is not to overload the charger, because the power quality gets much worse.

The charger is designed to reduce the switching frequency under low load for efficiency. I found this feature kicks in at loads under 1 amp, with the switching frequency smoothly dropping from 60 kHz to 29 kHz at 250 mA load and even lower under no load. The graph below shows the frequency spectrum at 250 mA load. Note that the spikes are wider than the previous case since the frequency becomes more unstable when it is reduced.

The output waveform below at 250 mA is similar to the previous (2A) case, except at a lower frequency. Note that the output still has large spikes when the transistor switches on. The output voltage drops while the switching transistor is on and then rises while the transistor is off (due to the flyback design), so you can see below that the transistor is off most of the time at low power.

Power consumption

Measuring the power consumption of a charger is tricky because the charger doesn't use power like a normal resistive load, but uses a nonlinear part of the input current. This results in a power factor lower than unity. (You might expect that the poor power factor is because the charger switches on and off thousands of times a second, but actually it's the fault of the diode bridge.) I measured the power consumption of the charger under load by measuring the instantaneous line voltage and current, computing the instantaneous power, and then computing the real power from this.[6] In the following diagrams, the input line voltage is shown in yellow, and the input current is in cyan. The instantaneous power is graphed in orange at the bottom - simply the product of the voltage and current.[7]The oscilloscope output below shows the power usage of the charger under no load. The line input voltage (yellow) is a nice sine wave, but the current (cyan) is very irregular. There is a bump corresponding to the voltage peaks as the input diodes conduct and re-charge the filter capacitors. The remaining current oscillations are unusual - I haven't seen them in other chargers, and I expect they are due to the large input choke. From the orange line you can see that the power usage has small spikes at 120 Hz. Taking the power factor into account and computing real power shows the charger uses 180 mW when idle which is fairly high, but actually lower than the Apple iPhone charger.

With load applied to the charger, the power usage shoots up as shown below. I compute the power usage as 6.4 watts, while the charger is supplying 4.4 watts to the output, for an efficiency of 69%. The shape of the current curve (cyan) and power curve (orange) shows that the charger is taking line power about half the time (the big curved peaks), and not for the other half (the flat oscillations in between). This illustrates the bad power factor that switching power supplies have. (PC power supplies often use power factor correction (PFC) circuits to improve the power factor.)The yellow input voltage curve is somewhat distorted, probably due to the lame isolation transformer I used.

You might wonder what happens if you short-circuit the output of the charger. It is designed to shut down before damage occurs, rather than self-destruct. After the internal voltage drops, the charger will start up again, and repeat this cycle until the problem goes away. This is called "hiccup mode", since the charger generates hiccups of power. The oscilloscope trace below shows the power consumption of the KMS charger when shorted. Note the pulses as it start up and shuts down every 250 milliseconds.

Components

For those who are interested in the components, I have some details. The two 6.8uF 400V electrolytic capacitors in the primary are made by ChengX. The two 470uF capacitors in the secondary are made by JWCO. The X capacitor is a .1uF K 275V X2 made by Dain Electronics, a Chinese manufacturer of plastic metal film capacitors, now merged with WINDAY Electronic Industrial Co Ltd. The Y1 capacitor is a JN222M 2200pF disk ceramic suppression capacitor manufactured by Jya-Nay, a Taiwanese capacitor company. There's also a blue 681J (i.e. .68nF) polyester film capacitor of unknown manufacturer; looking at the circuit board this capacitor (C7) was originally a surface-mounted device, but was replaced with a larger capacitor. The diodes are manufactured by MIC (Master Instrument Corporation, Shanghai). Most chargers use a diode bridge to convert the AC to DC, but this charger uses four independent diodes, which are 1N4007 700V diodes. The secondary rectification uses two Schottky diodes (SR360 3 amp 60V) from MIC. The circuit board uses the unusual mounting of two diodes on top of each other soldered into the same holes. The charger also uses FR107 700V fast recovery diodes.Like most power supplies, the charger uses a TL431A for the voltage feedback.[1] This TL431A is produced by Wing Shing Computer Components The optocoupler is an ORPC 817B optocoupler from Shenzen Orient Technology Co., Ltd. (I don't want to speculate on the cultural significance of their raising the flag over Iwo Jima company logo.)

Conclusion

The KMS charger occupies an interesting middle ground between dangerous $2 counterfeit chargers and expensive name-brand chargers. Tearing down this 4-port USB charger of unknown origin reveals details of the circuitry. It also illustrates a network of Chinese suppliers and manufacturers, most of which are hardly known in the US. On Amazon

Subscribe to:

Posts

(

Atom

)